Enhancing Medical Protection with Hydrophobic Masterbatch

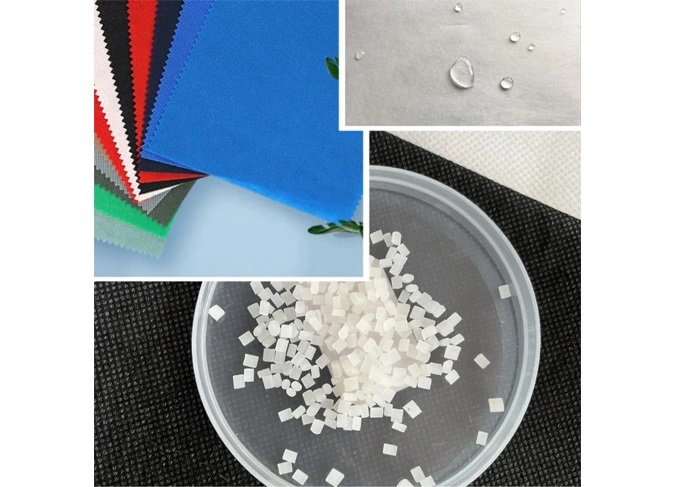

In the medical field, nonwoven fabrics are a crucial barrier between the human body and the external environment. They are used in surgical gowns, protective clothing, and medical masks to prevent direct contact with contaminants and bodily fluids. However, most polyolefin-based nonwovens, such as polypropylene, are naturally hydrophilic or semi-hydrophilic and can absorb moisture under certain conditions. This absorption compromises the integrity of protective layers, allowing fluid penetration and reducing hygiene standards. To solve this challenge, QIBO Technology has developed a high-performance hydrophobic masterbatch designed to increase the water-repellent properties of medical nonwovens. When integrated into the fiber extrusion process, the hydrophobic agent forms a stable molecular barrier on the fiber surface, significantly enhancing resistance to liquid penetration while maintaining excellent breathability and softness. This modification transforms standard nonwovens into reliable protective materials capable of blocking blood, body fluids, and contaminants effectively.

The Role of Hydrophobic Agent in Medical Nonwoven Protection

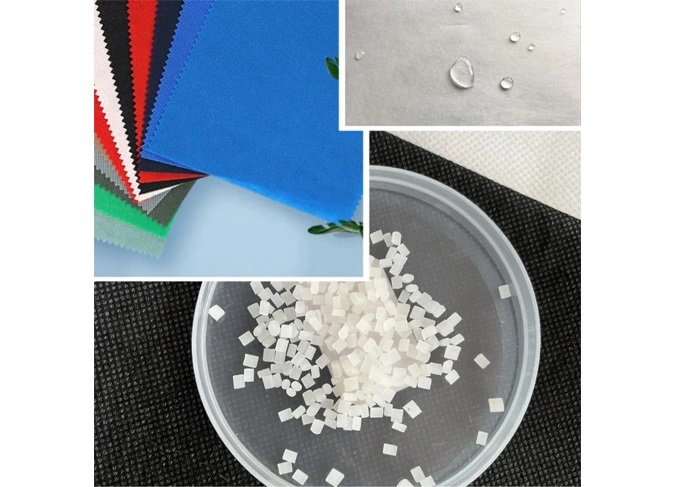

The hydrophobic agent in QIBO Technology's formulation works by lowering the surface energy of the nonwoven fibers, creating a strong repellent effect against polar liquids like water and biological fluids. When used in surgical gowns and medical masks, it prevents liquids from seeping through while allowing air and vapor to pass freely, which is critical for user comfort during long-term wear. The treated nonwoven fabric exhibits a high contact angle, meaning that drops of blood or other fluids bead up and roll off the surface rather than being absorbed. This feature not only enhances the barrier performance of the fabric but also helps maintain cleanliness and hygiene in sensitive environments such as operating rooms and laboratories. Unlike surface coatings that can wear off over time, QIBO's hydrophobic masterbatch is permanently integrated into the polymer structure, providing long-lasting repellency without affecting the texture or mechanical strength of the fabric.

Applications of Hydrophobic Masterbatch in Medical Nonwovens

QIBO's hydrophobic masterbatch plays a key role in manufacturing various types of medical nonwoven products. In surgical gowns, it ensures an impermeable barrier that protects surgeons and patients from cross-contamination caused by liquid splashes or biological fluids. In medical masks, it enhances the outer layer's resistance to droplets, preventing moisture absorption while keeping the material lightweight and breathable. In protective coveralls and isolation suits, the hydrophobic agent provides a dual effect—repelling fluids such as blood or disinfectant sprays while maintaining wearer comfort through air permeability. These functions are vital for frontline medical personnel who require both protection and mobility during extended use. The uniform dispersion of the hydrophobic agent throughout the fiber matrix ensures consistent repellency across the entire fabric, even after prolonged exposure to high humidity or sterilization processes.

How Does Hydrophobic Masterbatch Improve Nonwoven Performance?

The improvement in performance comes from the molecular engineering behind QIBO's hydrophobic masterbatch. The hydrophobic agent modifies the polymer chains to reduce their affinity for water molecules. This alteration increases the contact angle of the nonwoven surface, minimizing liquid spread and preventing absorption. The resulting nonwoven fabric maintains structural stability when in contact with fluids, avoiding the weakening or deformation that can occur with untreated materials. Furthermore, because the hydrophobicity is built into the fiber itself, it does not degrade with handling or sterilization. The masterbatch also enhances the fabric's resistance to microbial growth, as moisture accumulation is minimized. This added protection ensures that medical nonwovens remain hygienic, dry, and structurally sound throughout their lifecycle, offering a consistent level of defense in demanding medical environments.

QIBO Technology's Advanced Hydrophobic Solutions for Medical Safety

By applying advanced polymer modification and precise compounding processes, QIBO Technology has created a hydrophobic masterbatch that delivers exceptional stability, compatibility, and performance in medical-grade nonwovens. The hydrophobic agent is formulated to integrate seamlessly with polypropylene and other polymer substrates, ensuring even dispersion and consistent performance during melt-blown or spunbond production. This results in fabrics that effectively resist blood, body fluids, and chemical splashes while retaining their softness and flexibility. QIBO's hydrophobic masterbatch enhances the safety and hygiene of medical products without compromising user comfort or breathability, making it an ideal solution for medical masks, surgical gowns, and protective apparel. Through material innovation, it strengthens the invisible line of defense that ensures medical professionals and patients remain protected during every critical procedure.

English

English