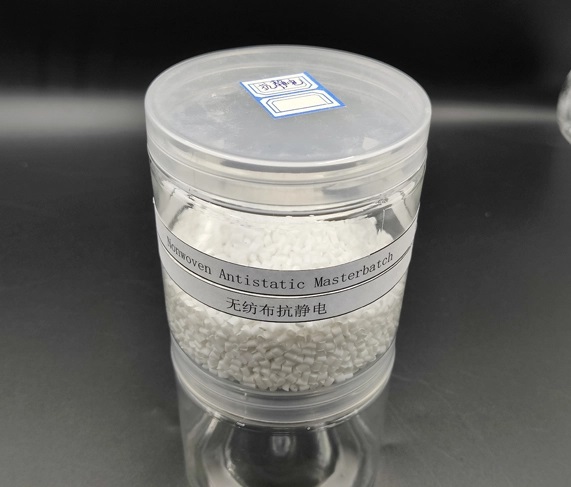

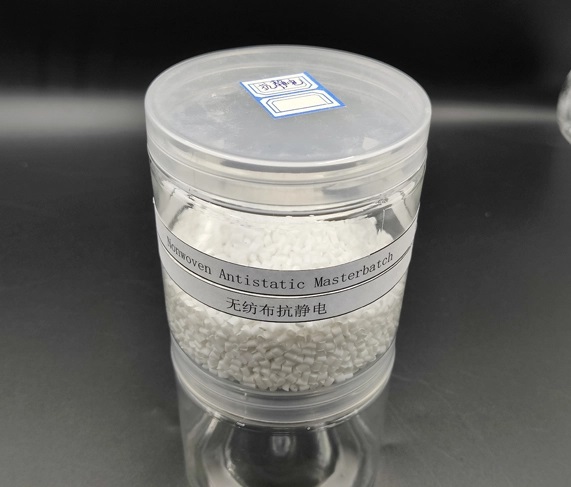

Advanced Anti Static Masterbatch Solutions for Nonwoven Applications

Nonwoven materials have become indispensable across industries such as hygiene, medical, filtration, and automotive manufacturing. However, due to their polymer-based composition, they are prone to static electricity buildup during production and use. Static accumulation not only attracts dust and contaminants but can also pose a safety risk in environments with flammable particles. To address these challenges, QIBO Technology provides high-performance anti static masterbatch designed specifically for nonwoven fabric applications. The masterbatch integrates advanced antistatic additives into polymer matrices like polypropylene (PP) and polyethylene (PE), effectively controlling surface resistance and ensuring consistent static dissipation. This technology enhances the cleanliness, safety, and overall reliability of nonwoven materials, meeting the strict standards of modern industrial and medical applications.

Creating Stable Electrical Performance in Nonwoven Fabrics

The anti static masterbatch from QIBO Technology delivers stable and long-lasting antistatic performance through uniform dispersion of conductive agents within the polymer. When incorporated into nonwoven materials during extrusion or spinning, the masterbatch establishes a controlled conductive network throughout the fibers. This prevents the buildup of electrical charges that typically occur during friction, transportation, or high-speed processing. Unlike surface coatings that may fade or wear off, the internal modification achieved by QIBO's masterbatch ensures durability and effectiveness over time. This makes it ideal for use in dust-sensitive environments such as cleanrooms, filtration systems, and electronic assembly spaces. The resulting nonwoven fabrics exhibit excellent handling characteristics and reduced electrostatic discharge risks, enhancing both production efficiency and operational safety.

How Does Anti Static Masterbatch Improve Nonwoven Safety?

The anti static masterbatch improves the safety of nonwoven materials by addressing one of the most invisible yet critical hazards—electrostatic charge accumulation. Static electricity can cause discomfort, attract airborne dust, or even ignite flammable gases in certain working environments. By incorporating QIBO's specialized masterbatch, the nonwoven fabric gains permanent or semi-permanent antistatic properties that allow it to safely discharge electrical charges. The mechanism works through ionic conductivity or surface moisture absorption, depending on the formulation. In applications such as medical gowns, masks, automotive interiors, and industrial filters, this antistatic effect reduces contamination risks and prevents sparks that may compromise safety. QIBO's solution thus transforms ordinary nonwovens into materials that silently enhance protection, ensuring user comfort and safety without visible alteration to texture or color.

Superior Processing Stability and Application Versatility

Beyond its antistatic function, QIBO Technology's anti static masterbatch offers exceptional processing performance and compatibility with various polymer systems. It maintains uniform melt flow behavior, ensuring smooth extrusion and fiber formation in nonwoven production lines. The masterbatch can be used in melt-blown, spun-bond, or needle-punched processes without affecting fiber softness or bonding strength. Its adaptability enables application in diverse sectors including hygiene products, automotive components, filtration fabrics, and protective materials. QIBO's formulations are also environmentally conscious—free from heavy metals and compliant with global safety standards. This balance between performance, safety, and sustainability highlights the company's expertise in polymer modification technology. With stable electrostatic control and reliable dispersion, the masterbatch ensures consistent performance even under varying humidity or temperature conditions.

Building a Cleaner and Safer Nonwoven Future

The role of anti static masterbatch in nonwoven materials extends beyond static control; it contributes to creating cleaner, safer, and more sustainable environments. As industries demand higher levels of safety and quality, the integration of advanced additive technologies becomes essential. QIBO Technology's dedication to material innovation ensures that nonwoven fabrics can meet the evolving needs of modern applications—from medical protection to industrial precision. Through its carefully engineered antistatic masterbatch, QIBO not only reduces electrostatic risks but also enhances the performance and safety of nonwoven materials used worldwide. This invisible layer of protection reinforces the idea that true safety lies within the fabric itself—quietly safeguarding users and industries alike.

English

English