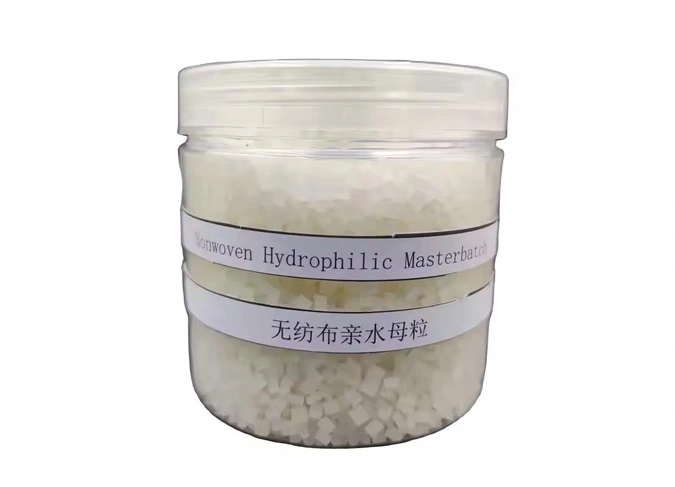

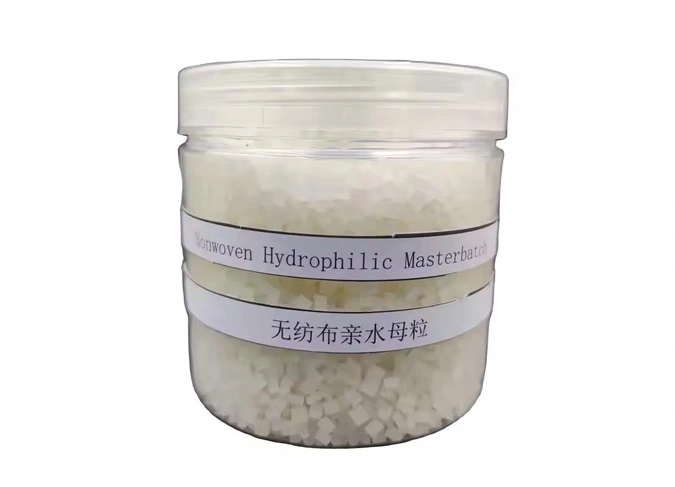

Enhancing Surface Performance with Hydrophilic Masterbatch

In the field of modern nonwoven production, surface performance plays a decisive role in determining the comfort, functionality, and usability of the material. Polypropylene-based nonwovens are widely used in hygiene, medical, and filtration applications due to their light weight and strength, but they naturally exhibit hydrophobic characteristics that limit their moisture absorption and liquid-spreading properties. To overcome this limitation, QIBO Technology provides advanced hydrophilic masterbatch solutions designed to improve surface energy and wettability. By incorporating a hydrophilic agent into the polymer matrix during extrusion, the surface of nonwoven fibers can be modified to attract and absorb water rather than repel it. This improvement transforms nonwoven materials from being water-resistant to moisture-absorbing, enhancing their practical performance in applications that demand fluid management and skin comfort.

How Hydrophilic Masterbatch Changes Nonwoven Surface Energy

The hydrophilic masterbatch developed by QIBO Technology works by altering the molecular polarity at the fiber surface. When a hydrophilic agent is introduced into the polymer, it migrates toward the fiber surface during processing, reducing surface tension and increasing surface energy. This change allows liquids to spread quickly and evenly across the nonwoven fabric instead of forming droplets. As a result, water and other fluids are efficiently absorbed, promoting rapid diffusion and reducing rewetting. This property is particularly important in hygiene products such as diapers, sanitary pads, and wipes, where fast liquid penetration ensures a clean and comfortable experience. The enhanced surface energy achieved through hydrophilic modification also improves the compatibility of nonwoven materials with coatings, laminations, and adhesives, expanding their usability across multiple industries.

Applications of Hydrophilic Agent in Nonwoven Materials

The inclusion of a hydrophilic agent within nonwoven fabrics opens a broad spectrum of functional possibilities. In hygiene applications, it provides superior fluid absorption and distribution, preventing localized wet spots and ensuring skin dryness. In medical nonwovens, hydrophilic masterbatch enhances fluid transport and breathability, which are crucial for surgical drapes, wound dressings, and protective wear. In filtration materials, it allows for efficient liquid permeation, improving filtration rates without compromising the structural integrity of the fiber. Additionally, agricultural nonwovens benefit from the ability to evenly distribute moisture, maintaining soil humidity and promoting plant growth. Across these applications, QIBO Technology's hydrophilic masterbatch ensures stable hydrophilic performance that withstands multiple uses and retains its effect after extended storage. The balance between wettability and mechanical durability makes it an essential additive for manufacturers seeking to enhance both performance and user experience in their nonwoven products.

Why Is Surface Energy So Important in Nonwoven Fabrics?

Surface energy determines how a material interacts with liquids, affecting its absorbency, printability, and coating adhesion. In nonwoven production, especially when using polyolefin polymers, surface energy is naturally low, leading to poor wettability. By integrating a hydrophilic agent, the surface energy of the fabric is significantly increased, allowing better interaction with aqueous systems. This improvement not only benefits product functionality but also contributes to more reliable processing performance in downstream applications such as lamination or printing. High surface energy also minimizes the need for secondary treatments like plasma or corona, simplifying production while maintaining consistent quality. Through continuous molecular-level improvement, QIBO Technology's hydrophilic masterbatch ensures that every fiber exhibits a balanced hydrophilic response, creating nonwovens that perform consistently under real-world conditions.

QIBO Technology's Commitment to Advanced Hydrophilic Solutions

QIBO Technology integrates precision formulation and advanced compounding processes to produce hydrophilic masterbatch products with consistent performance, high compatibility, and stable dispersion. Each hydrophilic agent is engineered to provide uniform wetting characteristics across nonwoven surfaces, ensuring that performance remains reliable in hygiene, medical, and industrial applications. The company's technical expertise ensures that the hydrophilic modification does not compromise fiber strength, softness, or color stability. This makes QIBO's hydrophilic masterbatch an ideal choice for manufacturers aiming to achieve enhanced absorbency and improved user comfort in nonwoven materials. By improving surface energy in a controlled and efficient manner, QIBO's solutions offer the invisible yet essential transformation that turns nonwovens into high-performance functional fabrics.

English

English