What Is Flame Retardant Masterbatch and How Does It Work?

Flame retardant masterbatch is a concentrated mixture of flame-retardant additives dispersed in a polymer carrier, designed to provide fire resistance to plastic products during manufacturing. Unlike loose additives, masterbatches ensure uniform dispersion of flame retardants, improving both safety and performance.

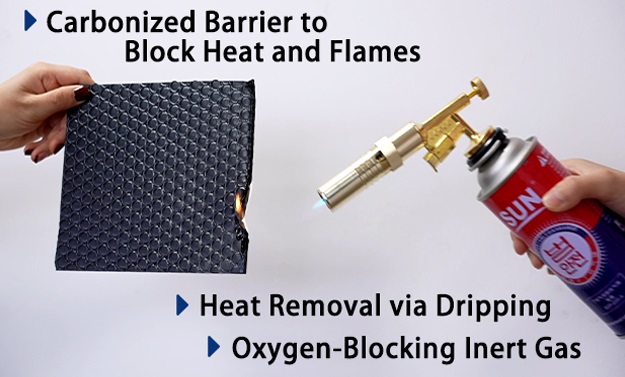

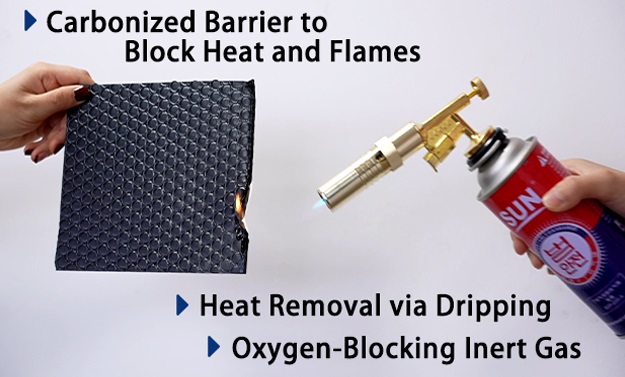

When flame retardant masterbatches are added to plastics, their mechanism of action is: when heated, they release a large amount of inert gas to isolate combustibles from oxygen, or form a protective carbon layer to prevent further combustion or take away most of the heat by dripping, thereby achieving a flame retardant effect. This makes it indispensable in industries where fire safety is critical. QIBO's flame retardant masterbatches are carefully designed to be environmentally friendly and efficient, and meet international safety standards such as UL94, RoHS and REACH, while maintaining material integrity.

Flame Retardant Masterbatch vs. Additives: Which Is Better for Your Application?

Deciding between flame retardant masterbatch and traditional powder additives depends on production requirements. Masterbatches offer better dispersion, easier handling, and reduced dust exposure, making them ideal for large-scale manufacturing. However, additives might be preferred when custom formulations require a specific ratio of components.

The table below highlights key differences:

Feature | Flame Retardant Masterbatch | Powder Additives |

Dispersion | Uniform, reduced agglomeration | Risk of uneven mixing |

Processing Ease | Pre-dispersed | Requires extra blending |

Dust & Safety | Dust-free, safer handling | Higher dust exposure |

Dosage Accuracy | More precise | Prone to measuring errors |

Cost Efficiency | Higher initial cost | Lower upfront cost |

For industries requiring precise, high-performance fire retardancy, QIBO’s masterbatch solutions provide a more reliable and efficient alternative to traditional additives.

Top Applications of Flame Retardant Masterbatch in Industry

Flame retardant masterbatch is widely used in sectors where fire safety is non-negotiable. In construction, it enhances the fire resistance of PVC pipes, insulation materials, and wiring systems, reducing the risk of electrical fires.

The automotive industry incorporates flame retardant masterbatch into dashboard components, battery casings, and interior trims to meet stringent fire safety regulations. Meanwhile, electronics manufacturers rely on it for plastic casings in appliances, switches, and circuit boards to prevent combustion hazards.

Additionally, the aerospace and defense sectors use flame retardant polymers in cable coatings and cabin interiors to maximize passenger safety. With increasing regulations worldwide, the demand for high-performance masterbatch continues to grow across various industries.

How to Choose the Right Flame Retardant Masterbatch for Plastics

Selecting the appropriate flame retardant masterbatch requires considering material compatibility, fire safety standards, and processing conditions. The first step is identifying the base polymer (PP, PE, ABS, etc.), as different resins require varying flame retardant chemistries.

Next, regulatory compliance must be assessed—industries like electronics and automotive often require halogen-free masterbatches to meet EU RoHS directives. Processing temperature is another key factor; high-temperature applications (e.g., engineering plastics) need thermally stable retardants to avoid degradation.

For manufacturers seeking optimized performance, QIBO’s technical team offers tailored solutions, ensuring the selected masterbatch aligns with both fire safety needs and production efficiency.

Innovations in Flame Retardant Masterbatch: Eco-Friendly Solutions

With increasing environmental regulations, the flame retardant industry is shifting toward sustainable, non-toxic formulations. Halogen-free masterbatches, which eliminate hazardous bromine and chlorine compounds, are gaining traction due to their lower environmental impact and compliance with global standards like REACH.

Bio-based flame retardants, derived from renewable sources, are another emerging trend, reducing reliance on fossil fuel-derived chemicals. Additionally, nanotechnology-enhanced masterbatches offer superior fire resistance at lower additive loadings, improving mechanical properties while maintaining eco-friendliness.

QIBO Chemical stays at the forefront of these innovations, developing high-efficiency, eco-compliant flame retardant masterbatches that meet both performance and sustainability demands.

Flame retardant masterbatch is a crucial component in manufacturing fire-safe plastics for industries ranging from construction to electronics. Offering better dispersion, safety, and processing efficiency compared to traditional additives, it ensures compliance with strict fire safety regulations.

For businesses seeking high-performance, environmentally compliant masterbatches, QIBO Chemical provides tailored solutions backed by expertise and innovation.

https://www.youtube.com/watch?v=8UMArqKa830

English

English